What Are the Best Tips for Serpentine Belt Longevity?

Did you know that a serpentine belt can last up to 60,000 miles before needing replacement? Ensuring the importance of this vital component in your vehicle's engine system is essential for smooth operation.

By following a few simple tips, you can greatly extend the life of your serpentine belt and prevent unexpected breakdowns.

Key Takeaways

- Regularly inspect and maintain the serpentine belt to catch issues early and ensure timely replacements.

- Properly adjust tension to prevent premature wear and maintain optimal performance.

- Avoid stress on the belt by aligning pulleys correctly and distributing loads evenly.

- Use high-quality replacement parts that are compatible and install them correctly for longevity and reliability.

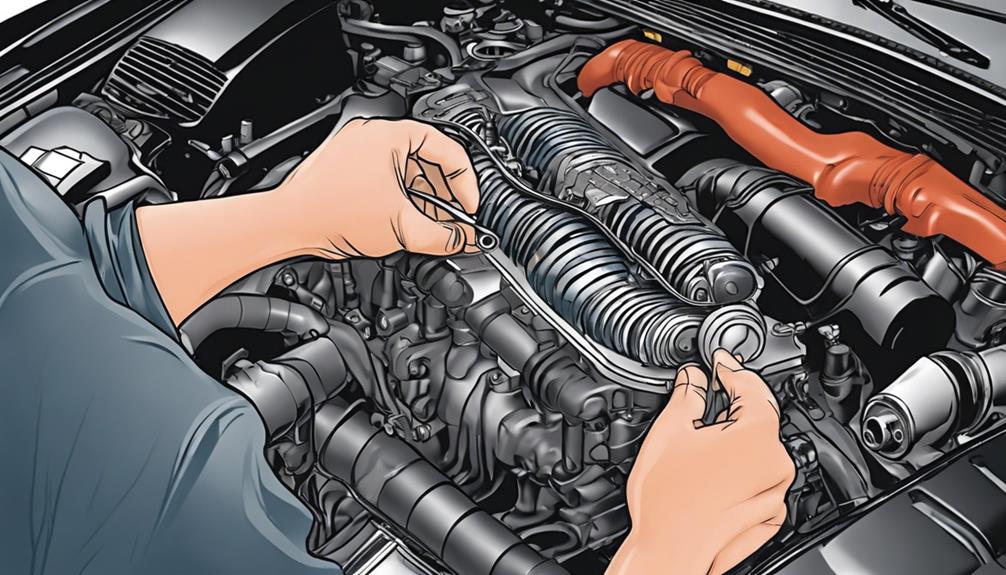

Regular Inspection and Maintenance

To guarantee top serpentine belt longevity, regularly inspect and maintain the belt according to the manufacturer's guidelines. Inspection frequency is important to catch any signs of wear or damage early on. It's recommended to visually inspect the serpentine belt every 12,000 miles or at least once a year, whichever comes first. During the inspection, look for cracks, fraying, glazing, or any other visible damage that may indicate the need for replacement.

Following a strict maintenance schedule is key to ensuring the serpentine belt's best performance and longevity. The maintenance schedule should align with the manufacturer's recommendations, which typically suggest replacing the serpentine belt every 60,000 to 100,000 miles. However, it's always best to consult your vehicle's manual for specific guidelines tailored to your make and model.

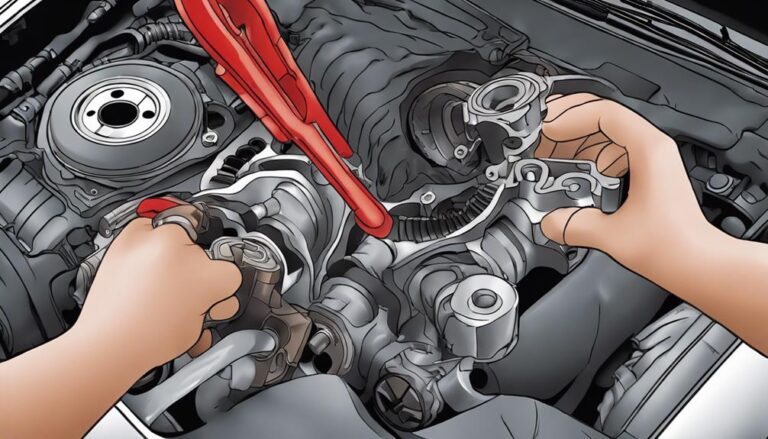

Proper Tension Adjustment

Maintain the proper tension of the serpentine belt to guarantee peak performance and longevity of the system. Incorrect tension can lead to premature wear and tear, affecting the overall efficiency of your vehicle.

To make sure your serpentine belt's peak function, consider the following:

- Regular Inspections: Check the tension regularly to prevent slippage or excessive wear.

- Utilize Tension Gauges: Use specialized tools like tension gauges to accurately measure the tension.

- Follow Manufacturer Guidelines: Adhere to the manufacturer's recommended tension specifications for your specific vehicle.

- Consider Heat Tolerance: Make sure the belt has appropriate heat tolerance to withstand engine temperatures.

- Evaluate Material Durability: Opt for belts made from durable materials to withstand the demands of the engine.

Avoid Excessive Stress on Belt

To prevent unnecessary strain on the serpentine belt, make sure that all pulleys are aligned properly with the belt's route for best performance and longevity. Proper alignment is essential to distribute the load evenly across the belt. When the pulleys are misaligned, it can cause the belt to twist or slip, leading to premature wear and potential damage. Ensure correct installation by following the manufacturer's guidelines for aligning the pulleys. Incorrect alignment can result in the belt riding off the pulley edges, causing friction and heat buildup that weaken the belt over time.

Proper alignment not only reduces stress on the belt but also improves overall system efficiency. A misaligned pulley can cause the belt to work harder to maintain traction, increasing wear on both the belt and the pulleys. Regularly inspect the alignment of all pulleys to identify any issues early on. By maintaining proper alignment and correct installation, you can greatly extend the life of your serpentine belt and avoid costly repairs.

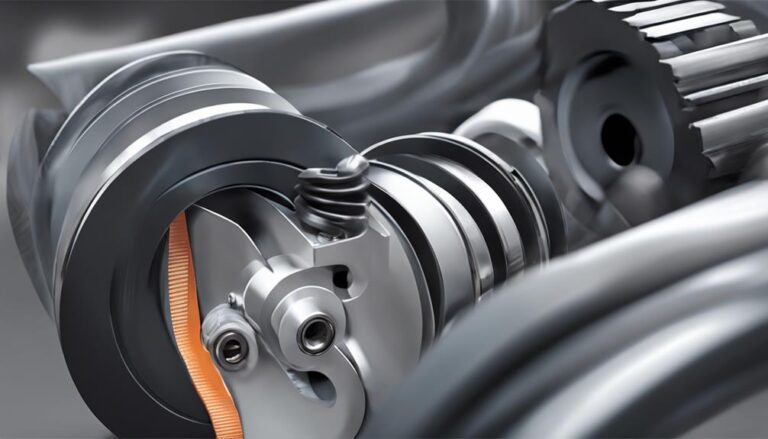

Keep Pulleys in Good Condition

Maintain pulleys are kept in best condition by regularly inspecting for signs of wear and damage. Proper pulley maintenance is important for ensuring the longevity of your serpentine belt system.

Here are some key tips to help you keep your pulleys in best condition:

- Check for Misalignment: Ensure that all pulleys are correctly aligned to prevent unnecessary stress on the belt.

- Inspect for Wear: Look for any signs of wear such as cracks, chips, or grooves on the pulley surfaces.

- Clean Regularly: Keep pulleys clean from debris and buildup to prevent interference with belt movement.

- Tension Adjustment: Check and adjust the tension of the belt to prevent slipping or excessive wear on the pulleys.

- Lubrication: If necessary, apply a small amount of appropriate lubricant to pulley bearings to maintain smooth operation.

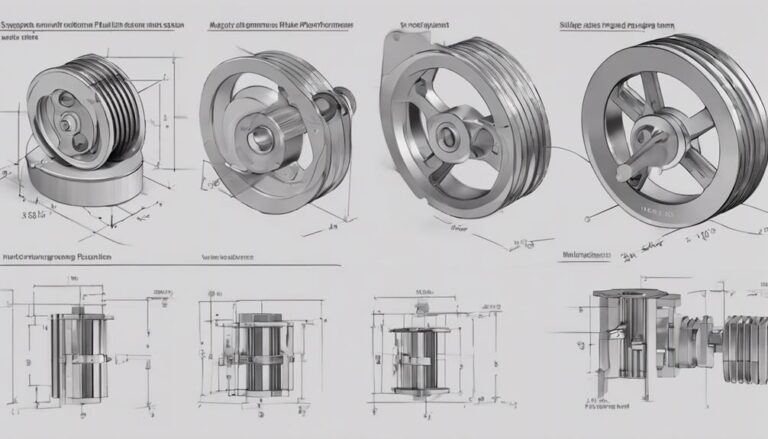

Use High-Quality Replacement Parts

Inspect the quality of replacement parts before installation to guarantee peak performance and longevity of your serpentine belt system. When selecting replacement parts, make sure they are compatible with the material of your belt to prevent premature wear and tear. Additionally, proper installation techniques are important to maintain the integrity of the belt and its components.

To help you choose the right replacement parts for your serpentine belt system, consider the following factors:

| Quality | Compatibility | Installation |

|---|---|---|

| Opt for high-quality parts to ensure durability and reliability | Check for belt material compatibility to prevent damage | Follow proper installation techniques to avoid premature wear |

| Look for reputable brands known for producing reliable components | Make sure the replacement parts match the specifications of your serpentine belt | Tighten bolts to the recommended torque to prevent slippage |

| Inspect for any defects or irregularities before installation | Avoid using parts that may cause excessive friction or tension | Align components correctly to prevent misalignment issues |

Frequently Asked Questions

Can Extreme Temperatures Affect the Lifespan of a Serpentine Belt?

Extreme temperatures can greatly impact a serpentine belt's lifespan. Climate changes can cause the belt to expand and contract, leading to wear and potential cracking. Regular inspection and maintenance can help mitigate the effects of temperature fluctuations.

What Are Some Signs That Indicate a Serpentine Belt May Need to Be Replaced?

When your vehicle's serpentine belt whispers with a high-pitched squeal or displays cracks, it's pleading for replacement. Belt tension and integrity are important. Neglect can lead to slipping, just like a dancer losing grip.

Are There Any Specific Driving Habits That Can Help Prolong the Life of a Serpentine Belt?

To prolong your serpentine belt's life, make sure proper tension and practice gentle acceleration. These habits reduce strain on the belt, preventing premature wear. By following these driving practices, you can maximize your serpentine belt's longevity.

How Often Should a Serpentine Belt Be Replaced as a Preventative Measure?

To guarantee proper belt tension and prevent breakdowns, replace serpentine belts every 60,000 to 90,000 miles as a maintenance measure. Regular inspections can help detect wear or damage early, allowing timely replacements to avoid unexpected failures.

Are There Any DIY Methods for Extending the Longevity of a Serpentine Belt, Aside From Regular Maintenance and Inspections?

To extend the life of your serpentine belt, try DIY methods like proper belt tensioning. Be mindful of temperature impacts on belt wear. These steps can help you maintain your belt's longevity between regular maintenance checks.

Conclusion

To make sure peak performance and longevity of your serpentine belt, it's crucial to conduct regular inspections, maintain proper tension, avoid excessive stress, keep pulleys in good condition, and use high-quality replacement parts.

By following these tips diligently, you can prolong the lifespan of your belt and avoid potential issues down the road.

Remember, a well-maintained serpentine belt is key to keeping your vehicle running smoothly.