why are brake lines coiled at the master cylinder

Introduction

Brake lines are coiled at the master cylinder for a variety of reasons. The most important reason is to reduce the amount of stress on the brake lines. This is important because the brake lines are responsible for transferring the pressure from the master cylinder to the brakes. Coiling the brake lines helps to reduce the amount of stress on the lines, which can help to prevent them from becoming damaged or leaking. Additionally, coiling the brake lines helps to reduce the amount of space needed for the brake lines, which can be beneficial in tight engine compartments. Finally, coiling the brake lines helps to reduce the amount of vibration that is transferred through the lines, which can help to reduce noise and improve the overall performance of the brakes.

Exploring the Benefits of Coiling Brake Lines at the Master Cylinder

The use of coiled brake lines at the master cylinder is becoming increasingly popular in the automotive industry. This is due to the numerous benefits that coiling brake lines can provide. In this article, we will explore the advantages of using coiled brake lines at the master cylinder.

The first benefit of using coiled brake lines is that they are more flexible than traditional brake lines. This flexibility allows for easier installation and maintenance of the brake system. Coiled brake lines are also less likely to kink or become damaged during installation, which can lead to a decrease in brake performance. Additionally, coiled brake lines are less likely to be affected by vibration, which can cause traditional brake lines to become brittle and eventually fail.

Another advantage of using coiled brake lines is that they are more resistant to corrosion. This is due to the fact that the coils are made from a material that is more resistant to corrosion than traditional brake lines. This increased resistance to corrosion can help to extend the life of the brake system and reduce the need for costly repairs.

Finally, coiled brake lines are also more aesthetically pleasing than traditional brake lines. This is because the coils can be painted or powder-coated to match the color of the vehicle, making them less noticeable. This can help to improve the overall look of the vehicle and make it more attractive to potential buyers.

In conclusion, coiled brake lines offer numerous benefits when used at the master cylinder. They are more flexible, less likely to kink or become damaged, more resistant to corrosion, and more aesthetically pleasing than traditional brake lines. For these reasons, coiled brake lines are becoming increasingly popular in the automotive industry.

How Coiling Brake Lines at the Master Cylinder Enhances Vehicle Performance

Coiling brake lines at the master cylinder is an important step in enhancing vehicle performance. This process involves winding the brake lines around the master cylinder in a specific pattern to ensure that the brake lines are properly routed and secured. This helps to reduce the amount of slack in the brake lines, which can lead to a decrease in brake pedal travel and an increase in braking power.

The coiling of brake lines at the master cylinder helps to reduce the amount of slack in the brake lines, which can lead to a decrease in brake pedal travel. This is because the slack in the brake lines can cause the brake pedal to travel further than necessary before the brakes are applied. By coiling the brake lines, the slack is eliminated and the brake pedal travel is reduced. This results in a more responsive braking system, as the brakes are applied more quickly and with greater force.

The coiling of brake lines at the master cylinder also helps to increase the braking power of the vehicle. This is because the coiling of the brake lines helps to reduce the amount of air that can enter the brake system. Air in the brake system can reduce the amount of pressure that is applied to the brakes, resulting in a decrease in braking power. By coiling the brake lines, the amount of air that can enter the brake system is reduced, resulting in an increase in braking power.

In addition to enhancing vehicle performance, coiling brake lines at the master cylinder also helps to ensure that the brake lines are properly routed and secured. This helps to prevent the brake lines from becoming damaged or disconnected, which can lead to a decrease in braking power.

Overall, coiling brake lines at the master cylinder is an important step in enhancing vehicle performance. By reducing the amount of slack in the brake lines and reducing the amount of air that can enter the brake system, the braking power of the vehicle is increased and the brake pedal travel is reduced. Additionally, coiling the brake lines helps to ensure that the brake lines are properly routed and secured, which helps to prevent damage or disconnection of the brake lines.

The Advantages of Coiling Brake Lines at the Master Cylinder

Coiling brake lines at the master cylinder offers several advantages. Firstly, it helps to reduce the amount of line needed to connect the master cylinder to the brakes. This is because the coiled line takes up less space than a straight line, allowing for a shorter overall length. Secondly, coiling the line helps to reduce the amount of pressure that is lost in the line due to friction. This is because the coiled line has less surface area than a straight line, which reduces the amount of friction that is created when the brake fluid is pushed through the line. Finally, coiling the line helps to reduce the amount of vibration that is transmitted through the line. This is because the coiled line is able to absorb some of the vibration, which helps to reduce the amount of noise that is created when the brakes are applied.

Overall, coiling brake lines at the master cylinder offers several advantages, including reducing the amount of line needed, reducing pressure loss due to friction, and reducing the amount of vibration and noise that is transmitted through the line.

The Mechanics Behind Coiling Brake Lines at the Master Cylinder

The coiling of brake lines at the master cylinder is an important part of the brake system. It is essential to ensure that the brake lines are properly coiled in order to ensure that the brakes are functioning correctly.

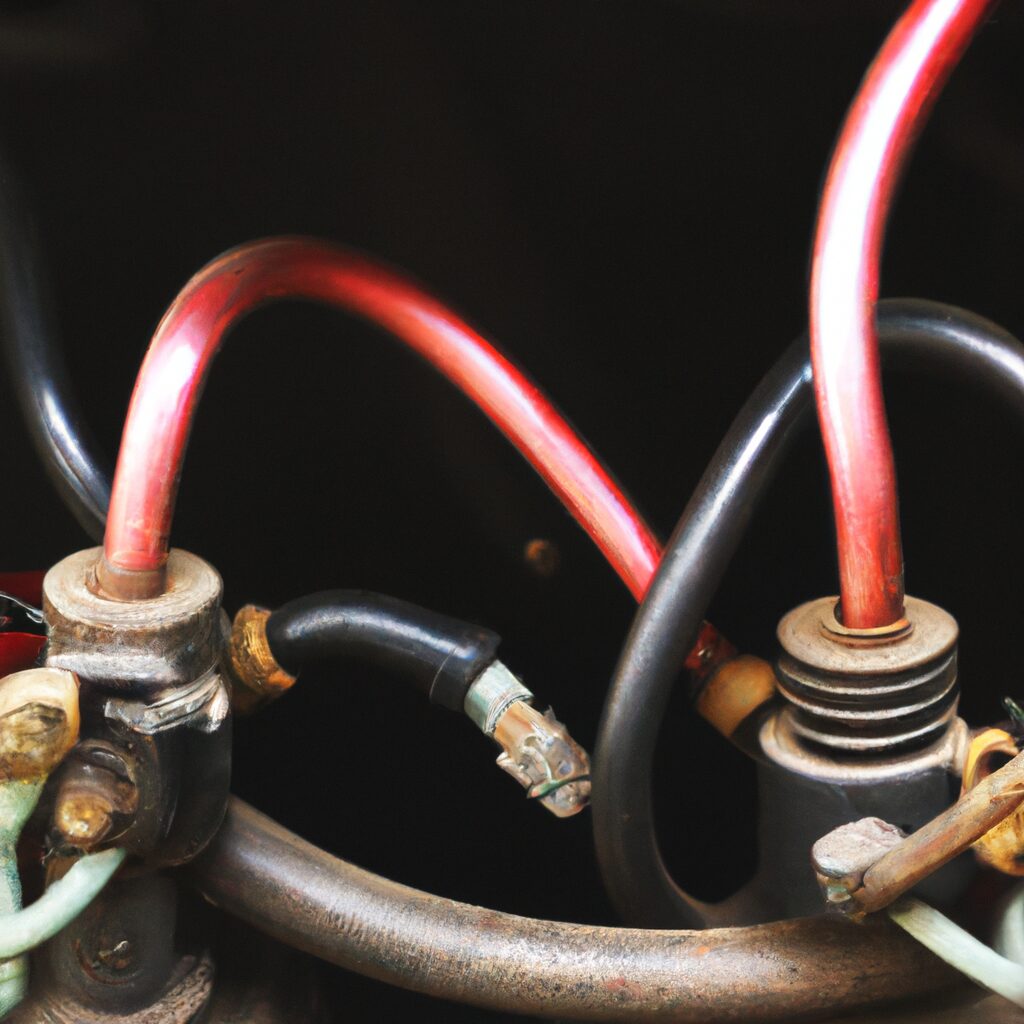

The process of coiling brake lines at the master cylinder involves several steps. First, the brake lines must be cut to the correct length. This is done by measuring the distance between the master cylinder and the brake caliper. Once the lines are cut to the correct length, they must be routed through the master cylinder. This is done by threading the lines through the mounting holes in the master cylinder.

Once the lines are routed through the master cylinder, they must be secured in place. This is done by using a clamp or a bracket to hold the lines in place. The clamp or bracket should be tightened to ensure that the lines are secure.

Once the lines are secured in place, they must be coiled. This is done by wrapping the lines around the master cylinder in a spiral pattern. The lines should be wrapped tightly to ensure that they are secure and that there is no slack in the lines.

Finally, the ends of the lines must be connected to the brake caliper. This is done by using a fitting or a connector. The fitting or connector should be tightened to ensure that the connection is secure.

Once the lines are coiled and connected, the brakes should be tested to ensure that they are functioning correctly. If the brakes are not functioning correctly, the lines may need to be adjusted or replaced.

Coiling brake lines at the master cylinder is an important part of the brake system. It is essential to ensure that the lines are properly coiled and connected in order to ensure that the brakes are functioning correctly.

The Role of Coiling Brake Lines at the Master Cylinder in Vehicle Safety

The coiling of brake lines at the master cylinder is an important safety feature in vehicles. This feature helps to ensure that the brake system is able to function properly and safely. The coiling of brake lines helps to reduce the risk of brake line failure due to excessive pressure or vibration.

When brake lines are coiled at the master cylinder, they are able to absorb the pressure and vibration that is created when the brakes are applied. This helps to reduce the risk of brake line failure due to excessive pressure or vibration. The coiling of brake lines also helps to reduce the risk of brake line corrosion due to moisture and other environmental factors.

The coiling of brake lines also helps to reduce the risk of brake line kinking. Kinking occurs when the brake line is bent too sharply, which can cause the line to become blocked or damaged. The coiling of brake lines helps to reduce the risk of kinking by allowing the line to bend more gradually.

The coiling of brake lines also helps to reduce the risk of brake line leakage. Leakage can occur when the brake line is not properly sealed or when the line is damaged. The coiling of brake lines helps to reduce the risk of leakage by providing a more secure seal.

The coiling of brake lines at the master cylinder is an important safety feature in vehicles. This feature helps to ensure that the brake system is able to function properly and safely. The coiling of brake lines helps to reduce the risk of brake line failure due to excessive pressure or vibration, corrosion due to moisture and other environmental factors, and kinking and leakage. By ensuring that the brake system is able to function properly and safely, the coiling of brake lines at the master cylinder helps to improve vehicle safety.

How Coiling Brake Lines at the Master Cylinder Reduces Wear and Tear

Coiling brake lines at the master cylinder is a common practice that helps reduce wear and tear on the brake system. This technique involves wrapping the brake lines around the master cylinder in a spiral pattern. This helps to reduce the amount of stress placed on the brake lines, which can cause them to wear out prematurely.

The coiling of the brake lines helps to evenly distribute the pressure along the length of the line. This prevents any one area from being overstressed, which can lead to cracks or other damage. Additionally, the coiling of the brake lines helps to reduce the amount of vibration that is transferred through the line. This helps to reduce the amount of wear and tear on the line, as well as the components connected to it.

The coiling of the brake lines also helps to reduce the amount of heat that is generated in the line. This is because the coiling helps to dissipate the heat more evenly, which helps to reduce the amount of heat that is transferred to the components connected to the line. This helps to reduce the amount of wear and tear on the components, as well as the line itself.

Overall, coiling brake lines at the master cylinder is an effective way to reduce wear and tear on the brake system. This technique helps to evenly distribute the pressure along the line, reduce the amount of vibration transferred through the line, and reduce the amount of heat generated in the line. All of these factors help to reduce the amount of wear and tear on the brake system, which can help to extend its lifespan.

The Impact of Coiling Brake Lines at the Master Cylinder on Vehicle Maintenance

Vehicle maintenance is an important part of keeping a car running smoothly and safely. One of the most important components of vehicle maintenance is the brake system. The brake system is responsible for slowing and stopping the vehicle, and it is essential that it is kept in good working order. One way to ensure that the brake system is functioning properly is to coil the brake lines at the master cylinder.

Coiling the brake lines at the master cylinder is a simple process that can have a significant impact on vehicle maintenance. By coiling the brake lines, it helps to reduce the amount of wear and tear on the lines, which can lead to fewer repairs and replacements. This can help to extend the life of the brake system and reduce the amount of money spent on maintenance.

Coiling the brake lines also helps to reduce the amount of noise that is produced by the brake system. This is because the coiled lines are better able to absorb vibrations, which can help to reduce the amount of noise that is produced when the brakes are applied. This can help to make the vehicle more comfortable to drive and can also help to reduce the amount of wear and tear on the brake system.

Finally, coiling the brake lines at the master cylinder can help to improve the performance of the brake system. This is because the coiled lines are better able to transfer the pressure from the master cylinder to the brakes, which can help to improve the responsiveness of the brakes. This can help to make the vehicle safer to drive and can also help to reduce the amount of wear and tear on the brake system.

In conclusion, coiling the brake lines at the master cylinder can have a significant impact on vehicle maintenance. By coiling the lines, it can help to reduce the amount of wear and tear on the brake system, reduce the amount of noise produced by the brakes, and improve the performance of the brake system. All of these factors can help to extend the life of the brake system and reduce the amount of money spent on maintenance.

Understanding the Necessity of Coiling Brake Lines at the Master Cylinder

The brake lines of a vehicle are an integral part of its braking system. They are responsible for transferring the hydraulic pressure from the master cylinder to the brakes, allowing the vehicle to stop. As such, it is important that the brake lines are properly installed and maintained. One of the most important steps in the installation of brake lines is the coiling of the lines at the master cylinder.

Coiling the brake lines at the master cylinder is necessary for several reasons. First, it helps to ensure that the lines are properly routed and secured. This prevents them from becoming tangled or damaged, which could lead to a loss of braking power. Additionally, coiling the lines at the master cylinder helps to reduce the amount of slack in the lines. This reduces the risk of the lines becoming stretched or kinked, which can also lead to a loss of braking power.

Finally, coiling the brake lines at the master cylinder helps to reduce the amount of vibration that is transmitted through the lines. This is important because vibration can cause the lines to become loose or damaged, leading to a loss of braking power. By coiling the lines at the master cylinder, the vibration is dampened, helping to ensure that the lines remain secure and in good condition.

In summary, coiling the brake lines at the master cylinder is an important step in the installation of brake lines. It helps to ensure that the lines are properly routed and secured, reduces the amount of slack in the lines, and dampens the vibration that is transmitted through the lines. By taking the time to properly coil the brake lines at the master cylinder, you can help to ensure that your vehicle’s braking system remains in good condition and operates as intended.

Q&A

1. Why are brake lines coiled at the master cylinder?

The brake lines are coiled at the master cylinder to provide flexibility and to reduce the risk of the lines becoming damaged or kinked due to vibration or movement of the vehicle. The coiling also helps to reduce the amount of pressure that is placed on the lines, which can help to extend their life.

Conclusion

The brake lines are coiled at the master cylinder to ensure that the brake lines are not stretched or kinked, which can cause a decrease in brake performance. The coiling also helps to reduce the amount of space needed for the brake lines, making them easier to install and maintain.