Cooler and Faster: The Benefits of Performance Intercoolers

While some may jest that intercoolers are merely automotive fashion accessories, those in the know understand their crucial role in engine performance. Performance intercoolers, the unsung heroes of the engine bay, significantly enhance vehicle speed and efficiency. This article delves into the technicalities of these critical components, evaluating their mechanics, features, and impact on engine cooling. It's time we liberate ourselves from ignorance and appreciate the intricate dance of power and coolness these devices provide.

Key Takeaways

- Performance intercoolers enhance engine power output and fuel efficiency.

- They reduce engine intake air temperature, improving engine performance and longevity.

- Performance intercoolers offer long-term economic advantages, with reduced maintenance expenses and increased efficiency.

- High-quality performance intercoolers use advanced materials and construction methods, ensuring durability and optimal cooling effectiveness.

Understanding the Role of Performance Intercoolers

While many may overlook their significance, performance intercoolers play an essential role in enhancing the efficiency and longevity of high-performance engines. These crucial components function as a type of heat exchanger, designed to cool air that has been compressed by the turbocharger or supercharger. This process is critical because when air is compressed, it naturally heats up, and hot air is less dense than cool air, providing less oxygen for combustion in an engine's cylinders.

Understanding the role of performance intercoolers, therefore, is vital for anyone seeking to maximize the potential of their vehicle's engine. The performance intercooler acts to cool the air before it reaches the engine, ensuring optimal combustion conditions and thereby improving both the engine's power output and fuel efficiency.

Performance intercooler piping is another element that should not be ignored. The piping connects the intercooler to the engine, and its size, shape, and material can significantly impact the performance of the intercooler. In essence, a well-designed and implemented performance intercooler system is a key factor in liberating the full potential of an engine, maximizing its power and efficiency while prolonging its operational lifespan.

The Basic Mechanics of Performance Intercoolers

During the operation of a high-performance engine, the role of performance intercoolers becomes crucial, as they function to rapidly cool down compressed air, enhancing the engine's overall efficiency and power output.

Intercooler installation involves strategic positioning in the engine's forced induction system. The intercooler acts as a heat exchanger, reducing the temperature of the air compressed by the turbocharger or supercharger. This cooling process increases the density of the air, allowing for more oxygen to enter the combustion chamber, resulting in a more powerful ignition and, consequently, increased engine power.

The effectiveness of intercoolers is often supplemented by high-flow air filters. These filters ensure that the air entering the intercooler is clean, free from debris, which could potentially compromise the intercooler's performance.

The system's sophistication extends to its design. The internal flow paths are designed to maximize heat exchange without significantly impeding airflow, ensuring efficient operation. Therefore, a performance intercooler not only enhances the engine's power but also contributes significantly to its durability by preventing excessive heat build-up.

Comparing Standard and Performance Intercoolers

In the realm of intercoolers, discerning the differences between standard and performance models necessitates a thorough comparison. This examination will encompass efficiency variations, a comprehensive cost analysis, and an overview of the respective installation processes. Through this comparative lens, we can elucidate the distinctive benefits and potential drawbacks of both standard and performance intercoolers.

Efficiency Differences

The efficiency of a standard intercooler versus a performance intercooler presents stark differences that are critical to understand.

- Performance intercoolers are designed to maximize cooling efficiency, resulting in less heat soak.

- They typically have larger surface areas than standard intercoolers, allowing for improved heat dissipation.

- The advanced materials used in performance intercoolers contribute to their superior heat transfer capabilities.

- Performance intercoolers often display better pressure drop characteristics, ensuring that the turbocharger performance is not compromised.

- They are engineered for optimal airflow, which can lead to increased power output from the engine.

In essence, these efficiency differences between standard and performance intercoolers can significantly affect the performance of your engine, giving you more power and reducing the risk of engine damage due to overheating.

Cost Analysis

Despite the apparent advantages of performance intercoolers over standard ones, it is essential to delve into a cost analysis for a thorough comparison, considering both purchase price and potential savings in maintenance and efficiency gains. Performance intercoolers, while having a higher upfront cost, offer considerable benefits in terms of improved engine efficiency and longevity, reducing long-term maintenance expenses. On the contrary, standard coolers, despite their lower initial price, may entail higher costs in the long run due to increased maintenance and lower efficiency. It is crucial to factor in these variables when making a purchasing decision. Therefore, performance intercoolers, despite their higher initial cost, may provide substantial economic advantages in the long run, contributing to their growing market appeal.

Installation Process

Moving forward, we will break down the installation process of both standard and performance intercoolers to better understand their respective complexities and efficiencies. To illuminate the process, consider these five key steps:

- Identifying the mounting area: The location must allow for optimal air flow and heat dissipation.

- Preparing for installation: This includes ensuring all necessary tools and parts are ready.

- Installing the intercooler: Careful alignment and secure fastening are essential.

- Connecting the piping: This ensures the efficient transfer of cooled air to the engine.

- Testing: After installation, a thorough test run ensures everything is functioning correctly.

Key Features of High-Quality Performance Intercoolers

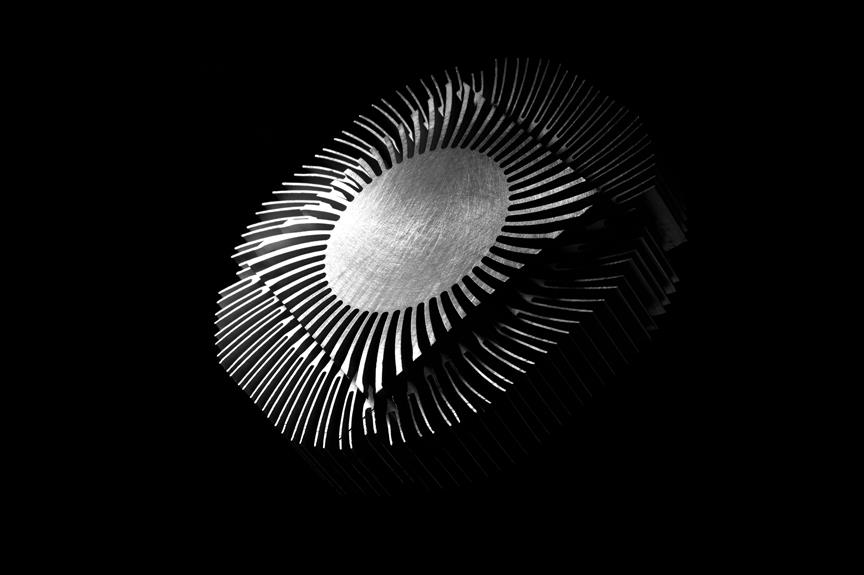

Evaluating the key features of high-quality performance intercoolers, two primary aspects stand out – material and construction, and temperature reduction efficiency. The material and build of the intercooler significantly influence its durability, heat resistance, and overall performance. Meanwhile, temperature reduction efficiency determines how effectively the intercooler can cool compressed air, directly impacting the engine's output and longevity.

Material and Construction

While the overall design of a performance intercooler is crucial, understanding the material and construction methodologies used in creating these vital components is equally important in assessing their quality and effectiveness.

Key features to look for include:

- Material: High-quality intercoolers are typically made from aluminum due to its excellent heat dissipation properties.

- Fin Density: A higher number of fins per inch can provide improved cooling efficiency.

- Construction Method: Bar and plate construction is generally more robust and efficient than tube and fin design.

- End Tanks: These should be designed to ensure even airflow distribution across the intercooler core.

- Intercooler Size: Larger intercoolers can provide better cooling, but they require more space and may impact vehicle aerodynamics.

Each of these factors plays a significant role in the performance and longevity of the intercooler.

Temperature Reduction Efficiency

The utmost measure of an efficient performance intercooler lies in its ability to significantly reduce intake air temperatures, thus enhancing the overall engine performance. A high-quality intercooler aims to achieve maximum temperature reduction efficiency through optimal design and material selection.

Let's examine the key features that contribute to temperature reduction efficiency:

| Key Feature | Description |

|---|---|

| Core Type | Bar-and-plate cores offer superior cooling efficiency over tube-and-fin designs |

| Core Size | Larger cores provide more cooling surface area but may introduce pressure drop |

| Fin Density | Higher fin densities allow better heat dissipation |

| End Tank Design | Properly designed end tanks ensure efficient air flow |

| Material | Aluminum is preferred for its excellent thermal conductivity |

Understanding these aspects can help performance-oriented individuals liberate their vehicles from the constraints of heat-induced power loss.

The Impact of Performance Intercoolers on Engine Cooling

Performance intercoolers play a crucial role in engine cooling by significantly reducing the temperature of the intake air charge. In turn, this lower temperature air charge leads to increased combustion efficiency and improved engine performance. This process, known as forced induction, is a critical aspect of modern internal combustion engines, particularly those found in high-performance vehicles.

Key impacts of performance intercoolers on engine cooling include:

- Reduction in engine intake air temperature: This is the primary function of the intercooler, leading to a denser intake air charge, which directly improves engine power output.

- Increased engine efficiency: Cooler air reduces the likelihood of engine knock, a damaging condition caused by premature ignition of the fuel-air mix.

- Enhanced engine longevity: Keeping the engine cooler helps reduce wear and tear, extending engine life.

- Improved fuel economy: The more efficient combustion process can lead to more miles per gallon.

- Potential for increased power: With more dense air, there's potential for the engine to safely handle more fuel, leading to greater horsepower and torque.

Performance Gains From Using Performance Intercoolers

An integral aspect of performance intercoolers is the significant performance gains they offer, particularly in high-powered vehicles. These enhancements are realized through the reduction of intake air temperature, which directly influences engine efficiency and output power. By optimizing heat exchange processes, high-performance intercoolers diminish thermal stress on the engine, mitigating the risk of detonation and enabling more aggressive tuning parameters.

As the intake charge air temperature is lowered, the air density increases, resulting in an enriched oxygen supply to the combustion chamber. This, in turn, facilitates a more complete combustion of the fuel-air mixture, leading to an increase in engine power output. Furthermore, these performance gains are typically accompanied by improved throttle response and a reduction in turbo lag, enhancing the overall drivability of the vehicle.

In contrast to standard intercoolers, performance intercoolers are designed with a larger core and more efficient fin designs. This not only facilitates superior heat dissipation but also minimizes pressure drop across the intercooler, allowing for optimal air flow to the engine. Consequently, the adoption of such high-performance intercoolers translates into tangible gains in horsepower and torque, providing a distinct performance advantage.

The Durability and Longevity of Performance Intercoolers

Boosting engine efficiency while simultaneously enhancing longevity, performance intercoolers are built for durability even under the most demanding conditions. These superior cooling systems embody the perfect fusion of strength, performance, and durability, ensuring they withstand the rigors of high-performance environments.

Performance intercoolers offer:

- *Superior materials*: Manufactured using high-grade, heat-resistant materials for longer lifespan.

- *Advanced design*: Engineered to provide consistent cooling, even under extreme stress.

- *Resistance to wear*: Constructed to resist wear and tear, reducing the need for frequent replacements.

- *Enhanced cooling capacity*: Designed to cool more efficiently, reducing engine wear and extending its lifespan.

- *Reliability*: Proven dependability in diverse and challenging environments.

Each attribute contributes to the overall robustness and longevity of the intercooler. The combination of superior materials, innovative design, and resistance to wear ensures that the intercooler can handle the heightened demands, while delivering consistent performance over an extended period. In essence, these intercoolers are designed not just to survive, but to thrive in high-performance settings.

Now that we've explored their durability and longevity, the next section will guide you through considerations when purchasing performance intercoolers. This will help you make an informed decision that best suits your specific needs and aspirations.

Considerations When Purchasing Performance Intercoolers

When shopping for a performance intercooler, both budget constraints and engine compatibility should play pivotal roles in your decision-making process. It's critical to ensure that the intercooler model is compatible with the engine's specifications, including its turbocharging system and airflow requirement. A mismatch can lead to suboptimal performance and, in worst-case scenarios, engine damage.

To aid in understanding the key features to consider, a comparison table is provided below:

| Feature | Consideration | Relevant Questions |

|---|---|---|

| Cost | Quality often correlates with price. Be wary of deals that seem too good to be true. | Is it within my budget? Is the price reflective of its quality? |

| Compatibility | Your engine's specifications should match the intercooler's characteristics. | Does it fit my car model? Does it support my engine's turbocharging system? |

| Brand Reputation | Established brands often provide reliable products and services. | Does the brand have a good reputation in the market? |

| After-Sales Service | A good warranty period and responsive customer service are invaluable. | Does it have a good warranty period? Is the customer service responsive? |

| Reviews | User reviews provide real-life data on product performance. | What do other customers say about this intercooler? |

Real-World Applications and Results of Performance Intercoolers

Understanding the real-world applications of performance intercoolers provides valuable insight into their effectiveness, and the actual results achieved further illustrate their integral role in optimizing engine performance. These cooling systems are used in various domains such as automotive, marine, and aeronautics to significantly reduce engine heat, thereby enhancing performance.

Notably, in high-performance vehicles, intercoolers are employed to maintain optimal engine temperature during demanding drives. This results in increased horsepower, torque, and overall engine efficiency. Let's delve into some specific benefits:

- They facilitate more consistent power output by maintaining a steady engine temperature.

- They increase fuel efficiency by reducing the heat that can cause pre-detonation or 'knocking'.

- They enhance the life expectancy of the engine by preventing overheating.

- They boost power output for high-performance vehicles by allowing a safer increase in boost.

- They improve throttle response, giving drivers a more direct connection to their vehicle's power.

The real-world results of performance intercoolers are tangible and measurable. By offering significant improvements in engine performance and efficiency, they provide a liberating sense of control and power for the driver, making them a sought-after upgrade for any performance-oriented vehicle.

Frequently Asked Questions

How Much Would It Cost to Install a Performance Intercooler in My Vehicle?

The cost of installing a performance intercooler varies based on vehicle type and intercooler quality. Typically, it ranges from $300-$1500, including parts and labor. High-end models or professional installations may increase the cost.

Are There Any Potential Downsides or Risks to Installing a Performance Intercooler?

Installing a performance intercooler presents potential downsides including higher initial costs, increased fuel consumption, and possible warranty voidance. Furthermore, improper installation may lead to engine damage, necessitating professional fitting for optimal functionality and safety.

Can Any Car Benefit From a Performance Intercooler, or Is It Only for Certain Models?

While most vehicles can technically accommodate a performance intercooler, its benefits are primarily realized in turbocharged or supercharged engines, which constitute about 21% of new cars, as these systems generate significant heat during operation.

How Often Does a Performance Intercooler Need to Be Maintained or Replaced?

The maintenance frequency of a performance intercooler varies, primarily depending on usage intensity. However, inspections should occur annually for optimal performance. Replacement need only occur when inspections reveal significant wear or performance issues.

Can Installing a Performance Intercooler Void My Car's Warranty?

Installing a performance intercooler may potentially void your car's warranty, depending on the manufacturer's terms and conditions. It's crucial to review your warranty details before making such modifications to your vehicle.

Conclusion

In conclusion, performance intercoolers present a remarkable advancement in automotive technology. They significantly improve engine cooling efficiency, enhance engine performance, and extend engine life. With their superior construction and durability, they provide a worthwhile investment for vehicle owners. Real-world applications yield tangible results, validating their effectiveness. Therefore, a shift towards the adoption of performance intercoolers is not just advantageous, but imperative for the next era of automotive innovation.